Five Star Race Car Bodies

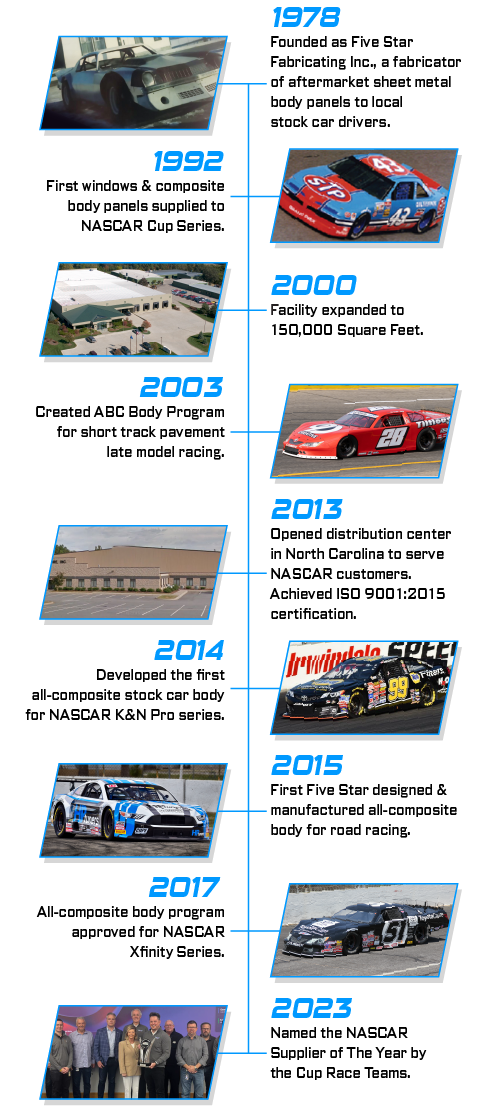

A division of Five Star Fabricating, Inc., was formed by Carl Schultz and Fran Prestay in the late 1970s in Twin Lakes, Wisconsin. Our company began as a side job for the two in response to a need for innovative sheet metal products in the stock car racing industry.

Fran owned an auto service shop across from Carl's local plumbing and heating business. After a rough night at the local short track, Fran asked Carl to produce a set of sheet metal fenders for his car since finding stock parts in the salvage yard was difficult and time consuming. The new fenders were a hit with other racers, who wanted them for their own cars. Seeing an opportunity, and eager to accept a challenge, Carl and Fran began producing components for the 1979 Camaro. Word of mouth and a small ad in Stock Car Racing Magazine led to a tremendous response from racers across the country.

From that '79 Camaro body, the product line quickly diversified and expanded to include tough and durable thermoformed polypropylene; lightweight, hand-laid fiberglass; and advanced composite race car body components. These additions moved Five Star to the forefront of the industry and laid out our path to becoming experts in manufacturing large, complex composite body panels that require both structural integrity and aesthetic quality.

Through the development and production of complete race car bodies, we perfected the art of formed windows. Our engineers devised improvements in material composition and coatings, which led to the development of our own superior line of polycarbonate. Five Star premium racing windows are now the #1 windows used in all motorsports.

By creating new standards in toughness, durability, and weather resistance, we have expanded our polycarbonate business outside of racing. Our high standard for quality parts and service has helped us form relationships with major brands across the transportation industry.

Advanced Body & Window Technology

Five Star continues to be dedicated to innovation. As we accept larger, more advanced projects and emerge into new markets and industries, we continue to maintain our deep roots in auto racing, putting our experience and expertise to work for you, our valued customers, by providing durable, high quality parts for years to come.

Five Star has been privately owned by the Schultz family since 2010. We lead the industry in manufacturing with over 175 employees and 300,000 square feet of floor space dedicated to the design, manufacture, and distribution of body panels, windows and accessories for NASCAR, Circle Track, Drag Race, Road Race, Off Road applications and much more. Our multi-unit facility is on the leading edge of technology, production capability, and logistics.

Our Philosophy

Our Family Values Drive Our Business

Five Star employees and their welfare are very important to the success of our company. Every employee is considered a member of our company team. Our success as a company is built on the recognition of the skills and efforts made by each employee. It is our policy to work with all members of our team in a fair and friendly manner and to treat each team member with dignity and respect. As a family-owned and operated business, we use the values of the Schultz Family as a guiding philosophy for running the business. These values are as follows:

INNOVATION - Progress, pushing boundaries, and creating groundbreaking solutions that shape the future.

WINNING - Resilience, determination, propelling individuals to overcome challenges and achieve their goals.

DEDICATION - Fueling individuals to put in the necessary effort and perseverance to succeed.

CUSTOMER FOCUS - Understanding and fulfilling the needs and expectations of customers.

EXCELLENCE - Surpassing ordinary standards, constantly striving for the highest level of quality, innovation, and achievement.

Career Opportunities

We are committed to these values and they are reflected in every area of our lives and how we do business. The adoption of these core values is essential to executing our strategy and ensuring a work environment that supports The Company’s objectives and inspires employees to new levels of productivity, helping them achieve their professional goals. We are confident in our ability to execute on our strategies making Five Star a fun, rewarding place to work.

State-of-the-Art Facilities

Five Star has expanded 12 times since 1986, operating out of 300,000+ SF of clean, modern manufacturing and distribution space in (3)

locations, totaling 34 acres.

1. Finished Goods & Plastic Forming

- Twin Lakes, WI

2. Composite Tooling & Design

- Twin Lakes, WI

3. Composite Production

- Twin Lakes, WI

4. Window Coating & Forming

- Twin Lakes, WI

5. Tooling Storage Facility

- Genoa City, WI

6. Dealer Service Center

- Concord, NC